INTRODUCTION

Gum ghatti (GG) is produced from the Anogeissus latifolia trees. Ghatti gum trees are found growing in dry deciduous regions (Meer, 1980; Meer, Meer & Gerard, 1973). GG is high molecular weight (~8.7 x 105) natural polymer. It is made up of biopolymer having monosaccharides along with hydrophobic glycoprotein moieties (Davidson, 1980). This gum is partially soluble in water and a part of it absorbs water and makes a gel or a viscous solution. It is insoluble in oil and organic solvent. Among natural exudate gums, GG possesses distinct viscosity and solubility properties in water and placed between karaya and arabic gums.

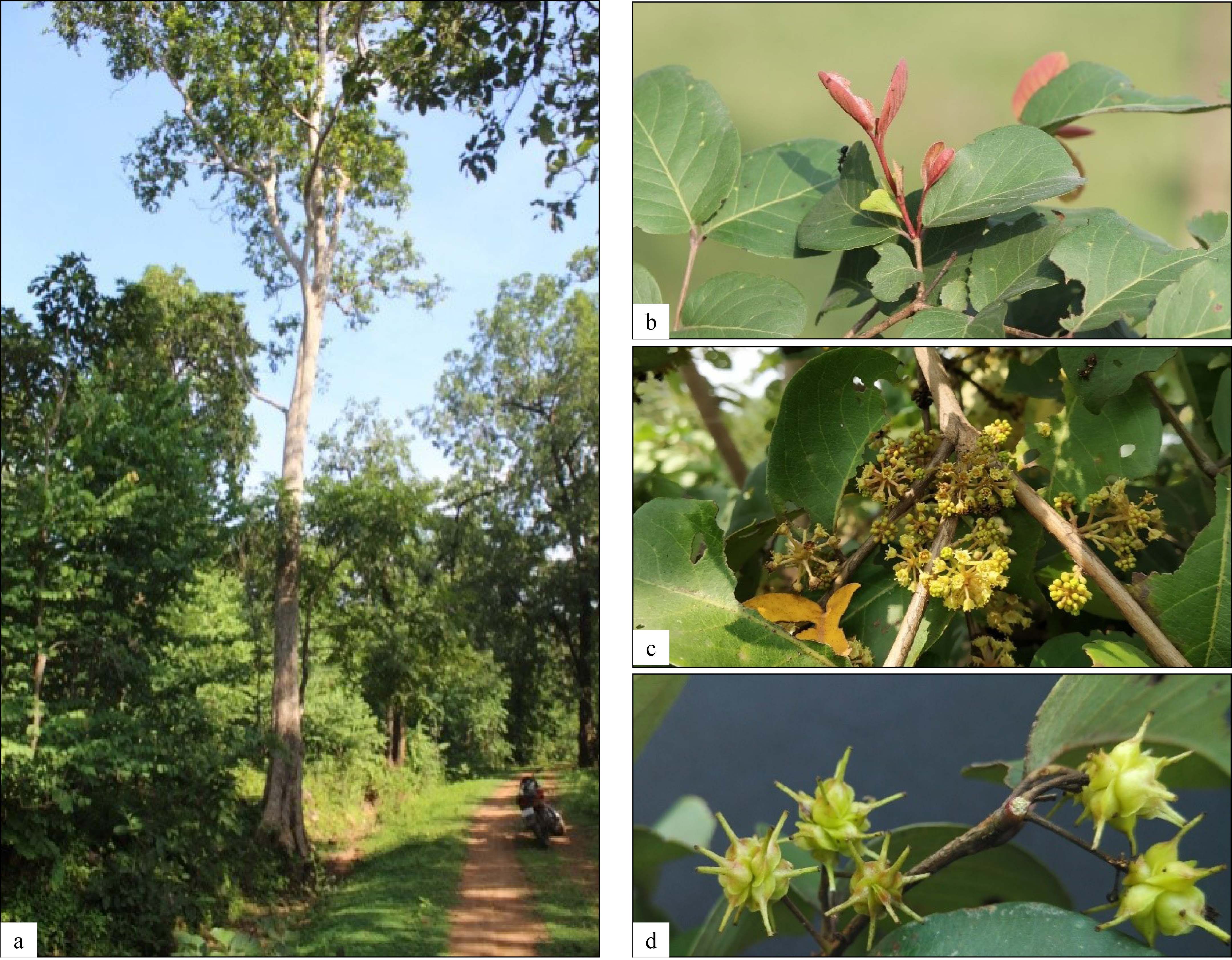

Description of A. latifolia tree

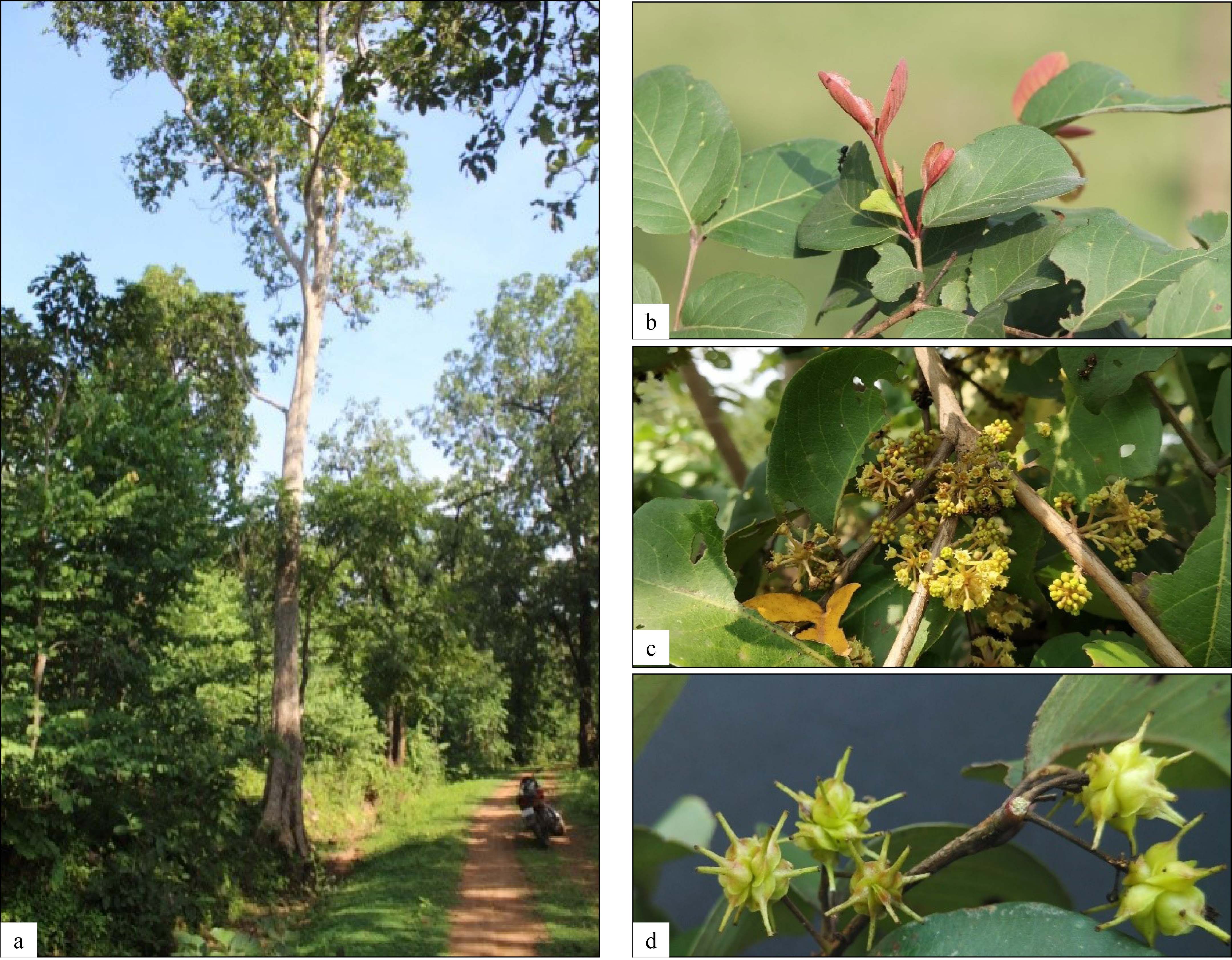

A. latifolia is a medium-sized tree growing up to a height of about 20 m (Fig. 1a). The tree’s bole is usually straight and cylindrical, having 0.8-1.0 m diameter. The tree remains branchless up to 8-10 m in height. The bark of this tree is smooth with scales and pale to dark grey. The leaves are simple, opposite, variably distichous, and exstipulate (Fig. 1b). The leaves have greyish-yellow or whitish hairs beneath. Young leaves are reddish-brown. Leaf fall in this tree takes place from February to May. Flowers are pale green to yellow, bisexual, and arranged in axillary, dense globose heads (Fig. 1c). The flowering takes place from June to September. Fruit is two winged pseudoachene shapes placed into a dense head (Fig. 1d). The fruit contains only one seed. The fruiting in this tree takes place from December to March. The leaves produce a large number of gallotannins which find application in the tanning industry. Apart from using this tree for gum ghatti production, its wood is used for timber purposes. (Thombare et al., 2018).

Figure 1. A. latifolia (a) tree, (b) leaves, (c) flowers, and (d) fruits

Geographical distribution of A. latifolia

A. latifolia trees grow in dry deciduous forests up to an altitude of 1100 m. This tree can grow in adverse climatic conditions with small water requirements. Usually, this tree grows in the valley (known as ghat in Hindi language) and hence locally known as the ghatti tree. This tree is found in most parts of India, except North-Eastern states, Himachal Pradesh, and Jammu & Kashmir. The ghatti tree is also found in Nepal, Bhutan, Myanmar, Pakistan, and Sri Lanka.

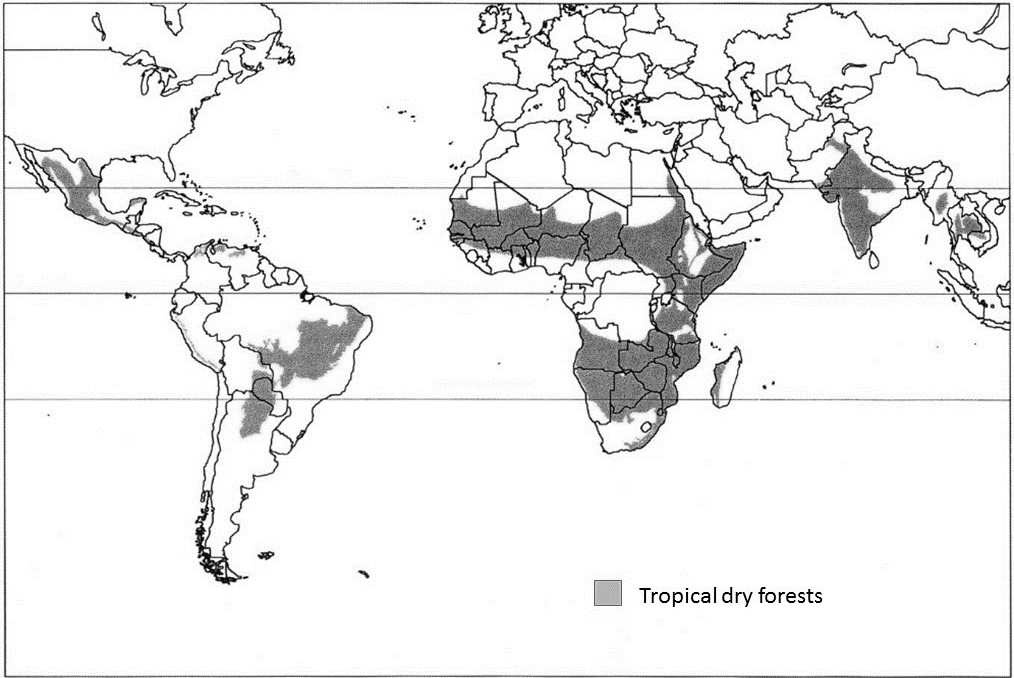

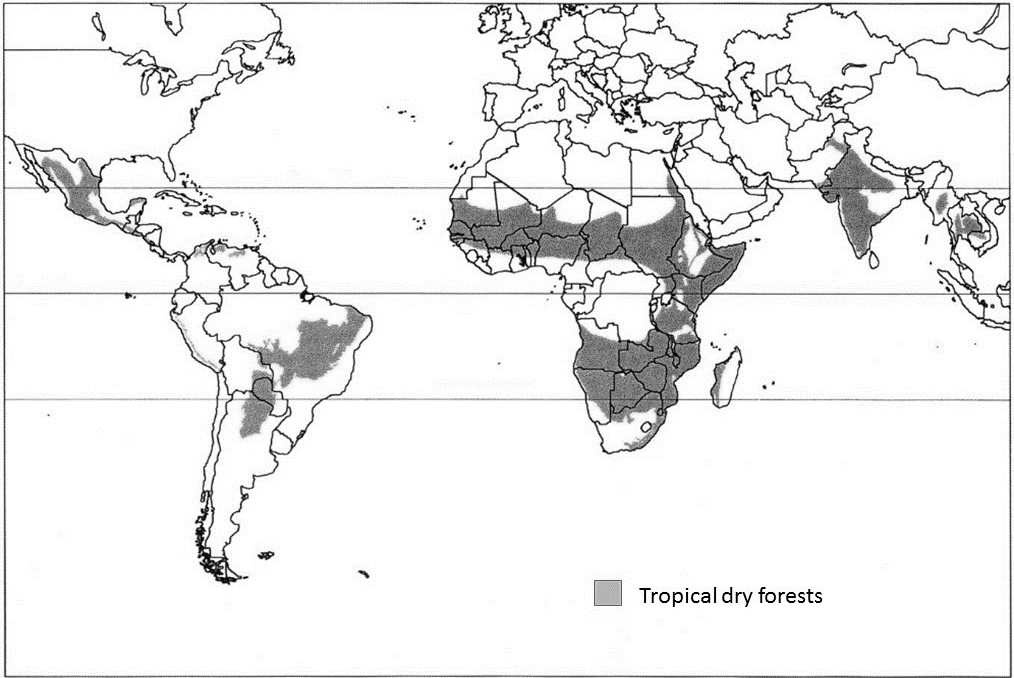

Figure 2. Global distribution of tropical dry forests (Bellefontaine, Gaston & Petrucci, 2000)

Scope of area expansion for A. latifolia and increasing GG production

Day by day, human beings are feeling the necessity of using natural products instead of synthetic materials, which is likely to increase the demand for natural gums like GG. There could be different ways by which GG production can be increased - (i) increasing GG production per tree by development and extension of the scientific method of GG tapping, (ii) bringing untapped A. latifolia trees under GG production, (iii) developing plantation of A. latifolia in areas where these trees are found growing and (iv) developing A. latifolia plantation in an area where these trees are not found but the climatic condition is suitable for growing these trees and taking production of GG.

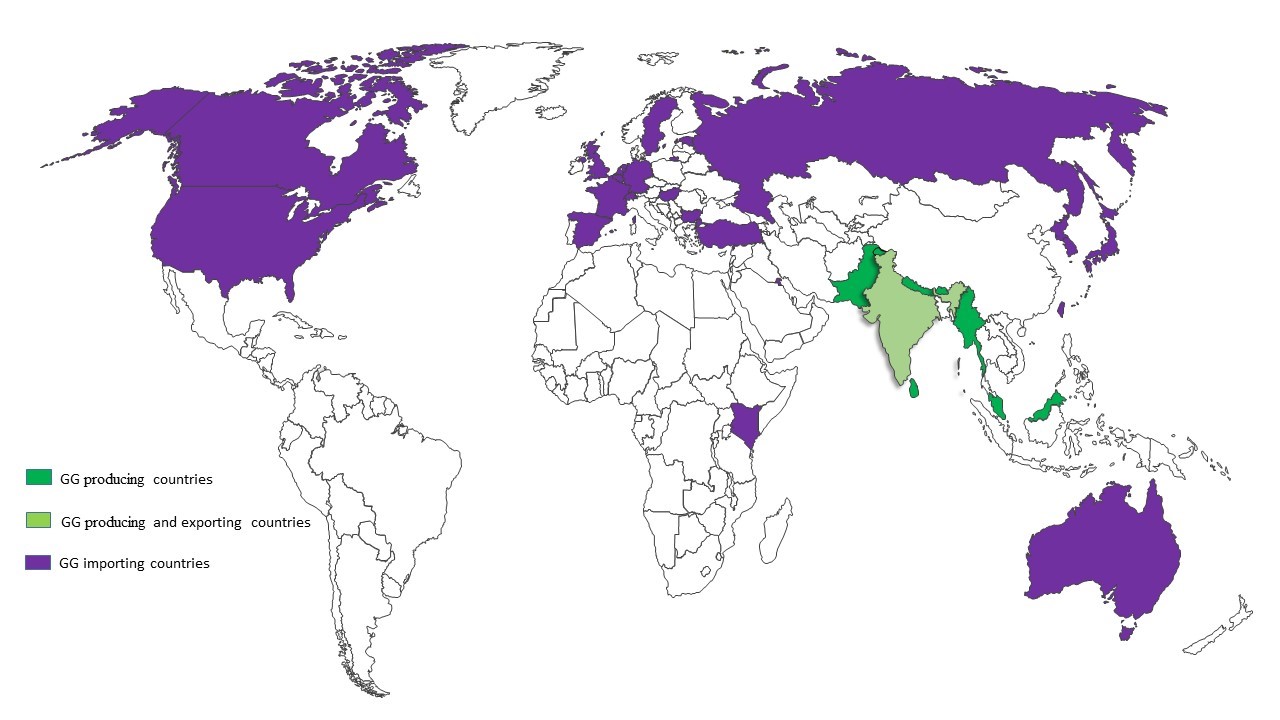

As it is found that A. latifolia trees are growing in dry/monsoon deciduous forests in countries like India, Nepal, Myanmar, Pakistan, Bhutan, and Sri Lanka, there is scope to plant more trees of A. latifolia in these regions. To further increase GG production, A. latifolia trees may be introduced in other countries having tropical dry/monsoon deciduous forests. Such countries may include Senegal, Mauritania, Venezuela, Vietnam, Cambodia, Thailand, Australia, Tanzania, and Kenya, as shown in Fig. 2. Introducing this tree will not only support the livelihood of the people residing in these forest regions but also help in carbon sequestration and climate change mitigation.

As GG is tree-based exudate gum, and time of more than 10-15 years for the A. latifolia tree to get mature enough for gum production after planting, there is scope to explore and carry out research for gum ghatti production in the laboratory by applying molecular, biological and biotechnological tools.

GG produced naturally, often gains colour from non-carbohydrate contaminants, and becomes darker. Previously, this gum could not find a place as a significant tree gum for use as food because of inconsistent supply and quality (Amar, Al-Assaf & Phillips, 2006). The United States of America has granted GRAS (Generally Recognized As Safe) status to GG since 1976, considering the desired result of teratogenicity, mutagenicity, and toxicity. In South American countries like Brazil, Colombia, Ecuador, Guatemala, Uruguay, and Venezuela, the GG is used as a natural emulsifier, thickener, and stabilizer. It is also permitted as a food emulsifier in Asian countries including China, India, Japan, South Korea, Singapore, and Russia. In Australia GG falls under the list of approved herbs and in South Africa, it is permitted as a food emulsifier (Al-Assaf, Phillips & Amar, 2009). In these countries, GG is used as a substitute for hydrocolloid in food applications as an emulsifier (Castellani et al., 2010). However, the European Food Safety Authority has not retained GG in the list of food additives due to a lack of detailed food safety evaluation data (BeMiller, 1973; Glicksman, 1982). GG is gaining importance in food applications as it is a better emulsifier (Castellani et al., 2010; Jefferies, Konadu & And, 1982; Jefferies et al., 1978; Jefferies, And & Phillips, 1977; Kaur, Singh & Singh, 2009) than arabic gum (Ido et al., 2008). Lower quantity requirement of GG compared with gum arabic to achieve desired emulsifying and thickening effect in food and other applications along with favourable and matching cost has paved the way for increase in demand for GG in future (Meer, Meer & Gerard, 1973).

Researchers have reviewed and published different reviews on chemistry (Amar, Al-Assaf & Phillips, 2006; Barak, Mudgil & Taneja, 2020; Meer, 1980), properties (Al-Assaf, Phillips & Amar, 2021), food applications (Barak, Mudgil & Taneja, 2020), pharmaceutical applications (Deshmukh et al., 2012), and industrial applications (Giri & Badwaik, 2022). There is no recent comprehensive review covering the production, processing, and marketing of GG. Such consolidated information in one place may be helpful for those interested in beginning work or already working on GG.

GUM GHATTI

Production

In A. latifolia trees, gum production occurs by natural or artificial injuries, mainly in the summer or dry winter. The dried exudate is harvested manually. GG is mainly tapped from March to mid-June (Kramer & Kozlowski, 1979). Gum producers make artificial cuts on the tree’s bark to increase gum production. The incisions need to be of small size and shallow to avoid injury to plants and sustainable gum production.

Gum formation and yield

In A. latifolia bark or wood, pre-formed gum-producing tissues are not found. Thus trees do not produce gum on their own. However, it has the potential to produce gum when it is injured. Natural injuries (e.g. branch breaking due to wind, injury caused by birds and animals) also lead to gum production. Ghosh and Purkayastha (1959) studied the anatomy of the gum cavities formed due to injury in the bark and cambial zone. GG is produced as tears or irregular masses, and the production is more in dry years (Ghosh & Purkayastha, 1959). Gum production from this tree depends on the height of the tree and climatic conditions, and the tapping method. On average, one tree produces ~1-2 kg of gum per tree in a year.

In A. latifolia tree, bud formation/shoot growth and flowering/fruiting occur from June to July and September to January, respectively. In these periods, trees utilize reserve metabolites for such growth. However, from April-May, there has been a minor growth activity in the tree, and there remains a higher reserve of metabolites in wood parenchyma. This appears to be the reason for the higher gum production during April-May compared with other months. As gum yields during April-May were about 21 times higher compared to December-January in the gum inducer method, it was suggested to utilize the A. latifolia tree for gum tapping during April-May and leaving the tree for the rest in the leftover period of the year (Bhatt, 1987). The size and shape of the gum tears produced depend on the external and internal environment conditions of the tree-like temperature, relative humidity, wind, shape/size of the fissure, and internal pressure in the tree. GG tears are produced mainly in two shapes, i.e., spiral (Fig. 3a) and round (Fig. 3b). GG possesses a glassy appearance and depending on the age of exudate, its colour ranges from dark red to translucent white (Al-Assaf, Phillips & Amar, 2009).

Figure 3. Shape of GG tears (a) spiral and (b) round

Conventional method of GG tapping

The gum is harvested from wild and untreated trees by tribal people by making an incision in the tree’s main stem with an axe. After making an incision, gum production starts from the incision and solidifies on drying. Gum collectors handpick the dried gum. To increase gum production, gum producers often harvest gum, which causes injury to the cambium, leading to a reduction in tree life in absence of injury-healing (Ghosh & Purkayastha, 1959). Traditionally trees are tapped to increase gum yield following different tapping methods, i.e., blazing, bark stripping, and making deep cuts on the tree with local tools like axes. This leads to making deeper and larger blazes for gum tapping.

Further, due to the lack of guidelines for blaze depth, size, and number per tree per season, gum tappers make deep and large blazes on the tree to get higher gum yield, which adversely affects tree health, and sometimes leads to death of the tree. Thus there is scope for developing a blazer that can make a blaze of desired depth and size. Further, there is a need to develop guidelines for blaze depth, size, and number per tree per season for sustainable tapping of gum from A. latifolia trees and maintaining the tree’s health.

Gum inducer method of GG tapping

Like other gum trees, A. latifolia trees are also sometimes treated with stress hormones like ethephon (2-chloroethyl phosphonic acid) to increase the gum yield. The gum yield is directly related to the concentration of ethephon. Bhatt (1987) studied the response of ethephon application on gum exudation from A. latifolia trees. Ethephon was applied in different concentrations (100, 200, 400, 800, and 1600 mg) of the active substance in a 4 ml solution. The study was carried out in April-May and December-January on the A. latifolia tree, free from visible defects and located in Shivrajpur and Dang forest of Gujarat state in India. A spectacular increase in gum production took place in response to 1600 mg ethephon treatment over other treatments in two seasons in three consecutive years. Gum yield was 21 times more in April-May compared with December-January (Bhatt, 1987). Kuruwanshi, Katiyar and Khan (2017) studied the response of gum inducers on gum yield from A. latifolia trees in the Raipur district in Chhattisgarh state of India in 2015 (Fig. 4a, 4b, 4c & 4d). The experiment had six treatments, i.e., T1 control (distilled water), different ethephon concentrations (T2 0.78%, T3 1.56%, and T4 2.34%), and IAA (T5 400 ppm and T6 800 ppm) and replicated thrice. The maximum gum production was observed in May followed by April, June, and March. The low humidity and high temperature in May could be the reason for highest gum production in May. The gum production was maximum in treatment in T4 (662 g), followed by T3 (394 g) and T2 (197 g). The minimum gum production was found in T6 (42 g). However, there was no gum production in control T1 (Kuruwanshi, Katiyar & Khan, 2017).

In the gum inducer method maximum gum production takes place from the hole made on the tree trunk for inducer injection or fissures present near the hole in the tree, unlike the Acacia senegal tree, in which mostly gum production takes place from branches, which are far away from the hole made for inducer injection. Thus, there is a possibility of inducer residue in the exudate gum produced from A. latifolia in the gum inducer method, which needs to be investigated.

Figure 4. Gum inducer method for A. latifolia (a) Hole making with the hand drill, (b) Introduction of gum inducer with the syringe, (c) Covering hole with moist clay, and (d) Gum exudation

Harvesting, processing, and storage

Harvesting

GG produced on tree either naturally or from man-made injury is allowed to dry before being removed in form of tears. GG when comes in contact with bark after exudation gains colour from bark and becomes darker. The dark colour GG is less advantageous to gum producers. Further, gum produced coming in contact with the bark gets fixed with bark on drying. As GG possesses very good adhesive properties, it adheres to the bark strongly, and while gathering tear, bark also comes along with tears, which is not desired. This problem is also observed in karaya gum. Kovel Foundation, Visakhapatnam, India developed an innovative method of karaya gum collection on polythene sheet (Prasad et al., 2022), which may also be effective in GG collection and harvesting. Gum tapping and harvesting from A. latifolia trees is carried out in the summer months, usually from March to June, as the temperature remains high and relative humidity low during this period, which are favourable conditions for gum production. The gum tears thus produced on the tree are harvested by gum pickers manually. At times gum pickers use locally made pruning knife for removal of GG tears from the tree. It was observed that during manual harvesting directly by hand picking hardly any gum producer wears gloves. To avoid bacterial or fungal contamination, use of gloves needs to be recommended.

Processing

The methods followed for processing GG are similar to those followed for gum karaya. GG harvested from trees may contain ~20% moisture on dry basis (d.b.). Often it may also contain foreign matter like bark, leaves, soil, sand, etc. Freshly exudated GG is white, but after coming in contact with bark, it gains colour. GG containing foreign matter and darker in colour is considered to be of inferior quality and fetches less return to the producer. Further GG containing more than 10% moisture (d.b.), is prone to bacterial and fungal infections. Thus the GG harvested by the producer needs to be dried to bring moisture below 10% (d.b.) and cleaned to remove foreign matter present. At the gum pickers level, hardly any processing is done. The cleaning and grading operations are done at the processing centers. Later gum is graded manually to different grades depending on foreign matter present in gum and gum colour. In some processing units, ghatti tears are ground into a fine powder and graded into different particle size powder as per consumer demand. During this process, impurities are separated from the gum powder using different methods (aspiration, shifting, and separation according to density). In some industries, the gum is converted into spray dried GG powder from the soluble fraction using spray dryers (Giri et al., 2008). There is a need to develop small and handy equipment for primary processing (cleaning and grading) of GG at the village level and train the GG producer for primary processing making them aware of its need and benefit.

Drying: GG contains ~30-35% moisture (d.b.) at the time of exudation from the tree. After GG exudation, natural drying takes place on the tree till it is harvested. At the time of GG harvest from trees, it contains ~20% moisture (d.b.). Initially, gum drying is faster, but as drying progresses case hardening takes place and the rate of drying becomes very slow. GG producer allows harvested GG to dry in sun for 5-10 days depending on weather conditions till moisture content comes below 10% (d.b.). Generally, gum producer dries GG in sun by spreading gum tears on cloth/plastic sheet/mat (made up of bamboo/palm tree leaves/date tree leaves), kept on the ground. Kovel Foundation, Visakhapatnam suggested sun drying gum karaya on a raised platform made up of wooden poles, bamboo mat, and polythene sheet to avoid any contamination during drying by pets and children (Prasad et al., 2022), which may also be followed for GG drying. At ICAR-IINRG, Ranchi, India a small-scale dryer was developed for quickly drying gum and to avoid mixing of foreign matter (Annual Report, ICAR-IINRG, 2013), which may be recommended for GG drying also.

Cleaning and grading: Mostly cleaning and grading of GG is done manually or mechanically in processing industries. Rarely any processing is carried out at the GG producer level. The GG received in the processing industry is subjected to drying. After drying, GG is cleaned to remove foreign matter (bark, leaves, soil, sand, etc.). The large size impurities are removed by hand-picking and winnowing, whereas fine impurities like soil and sand are separated using sieves. After cleaning GG is graded based on colour and the foreign matter still present in the gum. The higher grades of GG are lighter in colour and possess less foreign matter compared to inferior grades. There is a scope of using colour sorter for grading GG based on colour.

Storage and transportation

The storage and transportation of GG is done mainly in burlap bags of 50 kg capacity. Semi-processed and processed GG which is usually in kibbled, granules, and powdered form is transported in drums, polythene-lined, multi-layered craft paper bags or cardboard boxes. GG agglomerate and lumps formation occurs in a damp environment. As GG is used in several food and pharmaceutical applications, the storage of GG is recommended in cool and dry warehouses for extended shelf-life (Giri et al., 2008). In the process of literature review, no study related to GG storage and change in properties with the time of storage was found. Thus there is the scope of taking such research work for important gum like GG.

Quality control

The grades of GG vary from one another in terms of colour, solubility, viscosity, bark and foreign organic matter (BFOM), and total ash content. GG is exported to different countries in three grades, i.e., No. 1, No. 2, and Unassorted grades (Table 1). The No.1 grade appears lighter in colour (off-white to buff) and has low ash content and higher viscosity. Number 2 grade appears brown to light amber in colour, and the unassorted grade appears dark brown to nearly black. There is a BIS specification IS 7239:1974 for food-grade GG (Anonymous, 1974). GG is also graded based on colour into different grades (red, yellow, and white). These different colour-based grades are further graded based on foreign matter in the gum. The spray-dried GG has good solubility, and the persistent colour is also known as ‘gatifolia’ (Kang et al., 2011).

The GG market has four segments based on grade, application, function, and geography (Table 2). According to grade type, GG is segmented into No. 1, No. 2, Unassorted, and spray dried grades. Based on application type, GG is segmented into beverages, paper manufacturing, dairy/frozen dessert, and confectionary. Considering the function, the GG market is segmented into thickening, binding, and gelling types. Regarding geography, the GG market is categorized into six regions, including Latin America, North America, Europe, and Asia-Pacific excluding Japan (APEJ), Japan, and Middle East-Africa.

Table 1. Grades of GG with their characteristics.

|

Grade

|

Characteristics

|

Approx price/Kg (INR)

|

|

No.1

|

This grade of gum has a lighter colour (Off white to buff) and has low ash content and higher viscosity.

|

500 - 600

|

|

No. 2

|

This grade is brown to light amber in colour and has less viscosity than Grade No. 1.

|

300 - 400

|

|

Unassorted

|

This grade is dark brown to nearly black.

|

100 - 150

|

|

Spray dried (gatifolia)

|

The spray-dried GG has good solubility and a persistent colour.

|

1000 - 1200

|

Table 2. Segmentation of GG market based on grade, application, function and geography (“Ghatti Gum Market - Global Industry Analysis 2025,” 2022).

|

GG market segmentation criteria

|

|

Grade

|

Application Type

|

Function

|

Geography

|

|

1. No.1,

2. No. 2, and

3. Unassorted

4. Spray dried

|

1. Beverages,

2. Paper manufacturing,

3. Dairy,

4. Frozen dessert, and

5. Confectionary

|

1. Thickening,

2. Binding, and

3. Gelling

|

1. Latin America,

2. North-America,

3. Europe,

4. APEJ,

5. Japan, and

6. Middle East-Africa

|

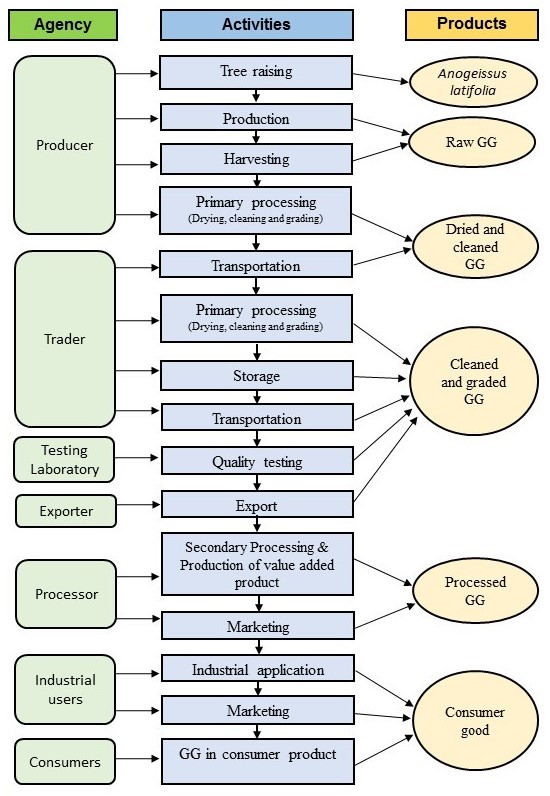

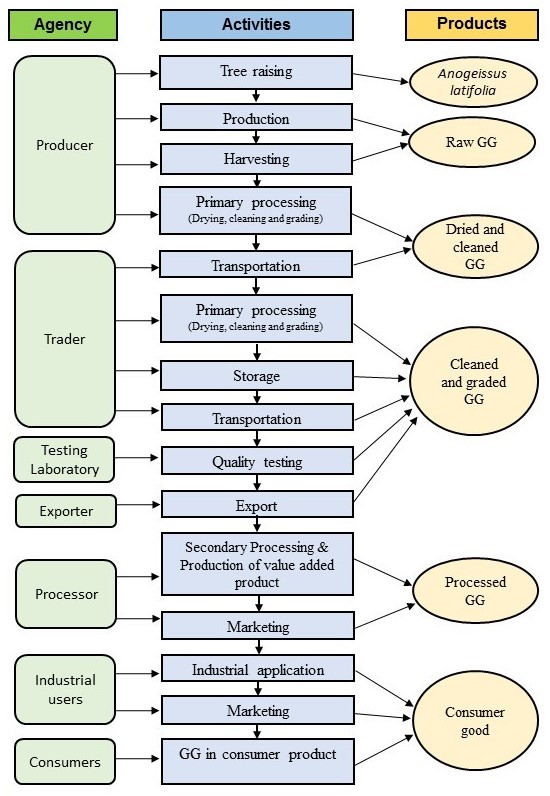

Value chain of GG

The value chain diagram on GG is presented in Fig. 5. The diagram includes activities associated with GG production to consumption and agencies from producer to consumer, emphasizing value addition at the different consecutive stages. The activities include GG plant raising, gum production, drying, cleaning, sorting, grading, transportation, storage, processing and value addition, marketing, and utilization. Before GG reaches the end-user, activities like sorting and grading, transportation and processing, and value addition may be done several times at various stages and destinations, comprising millions of associated stakeholders under the GG value chain. Most stakeholders in the value chain are producers in GG-producing countries, including gum tappers and collectors. Other associated people in the GG value chain include professionals like input suppliers, local business people, traders, processors, persons involved in storage and transportation, exporters and importers, processors, and users of different industries and government sectors.

Figure 5. Simplified value chain of GG.

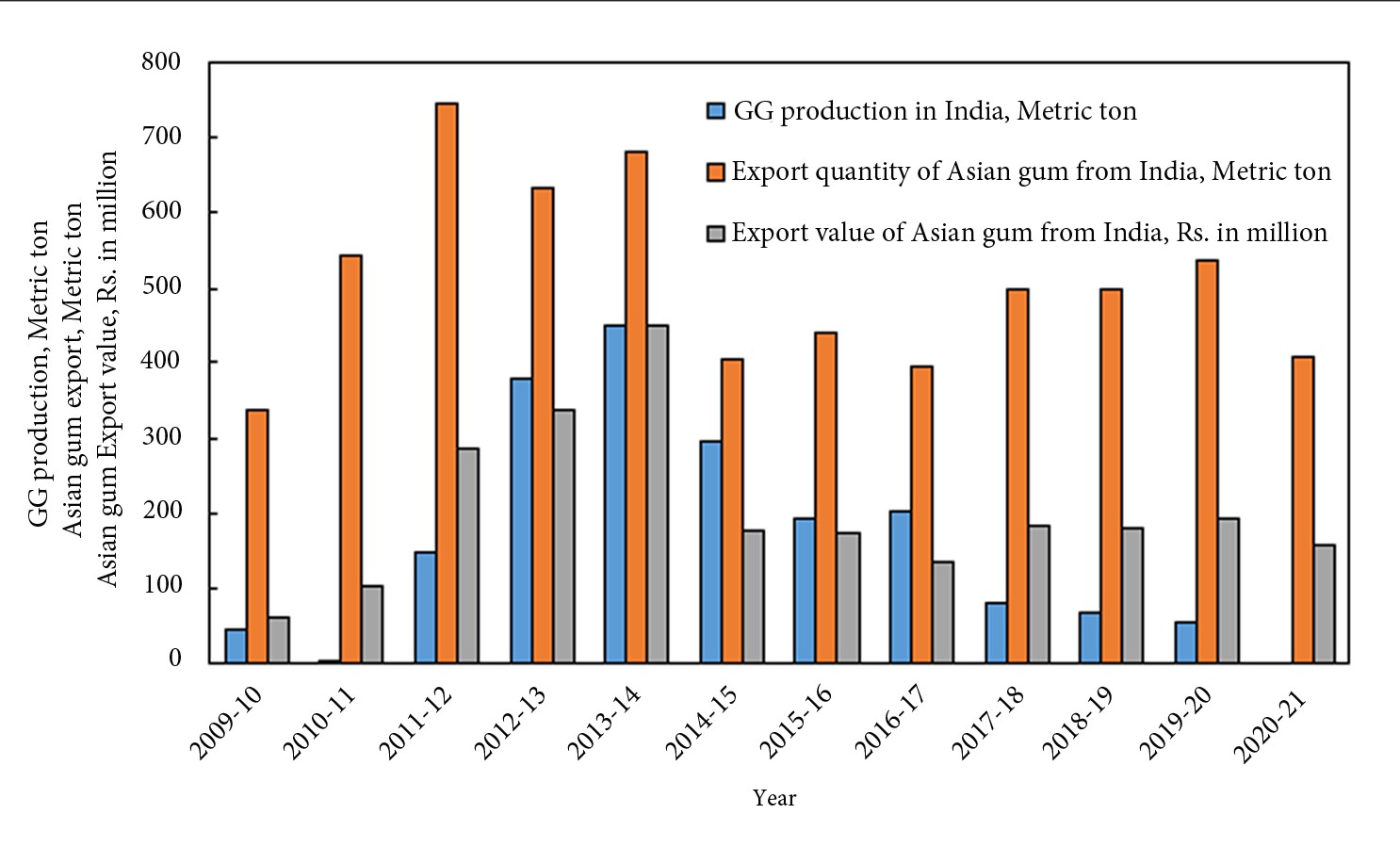

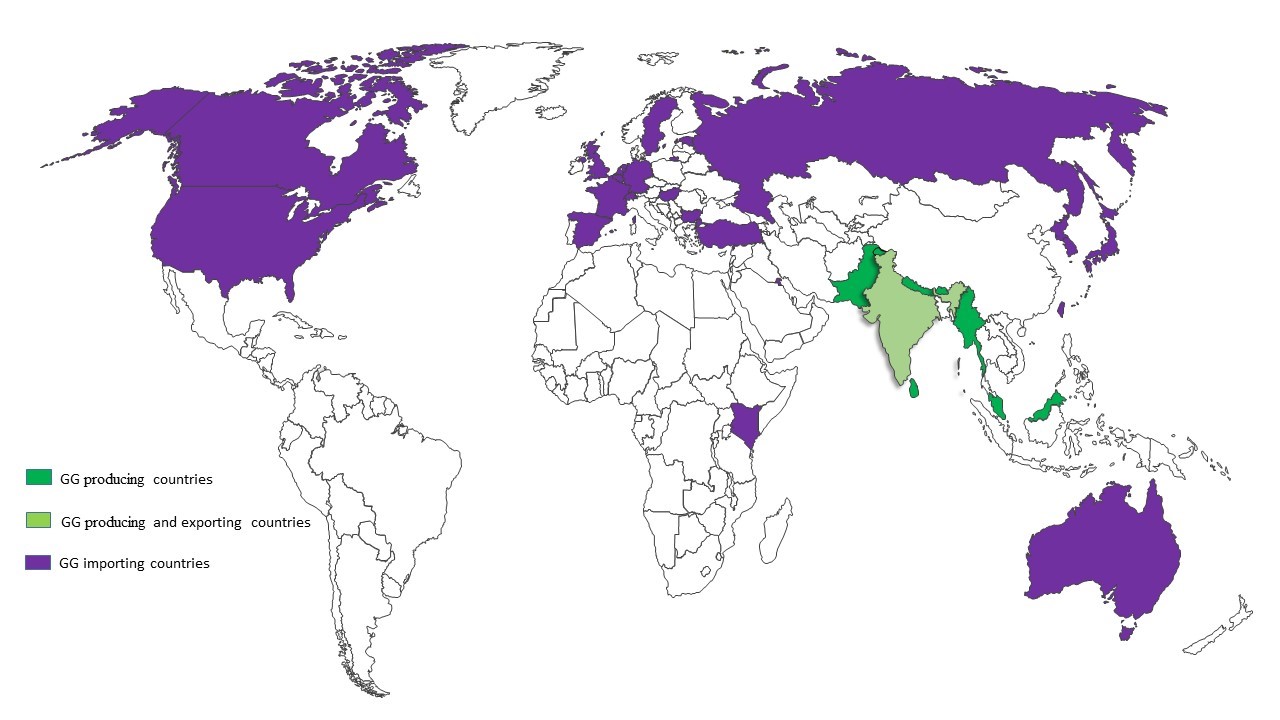

Production and Marketing of GG

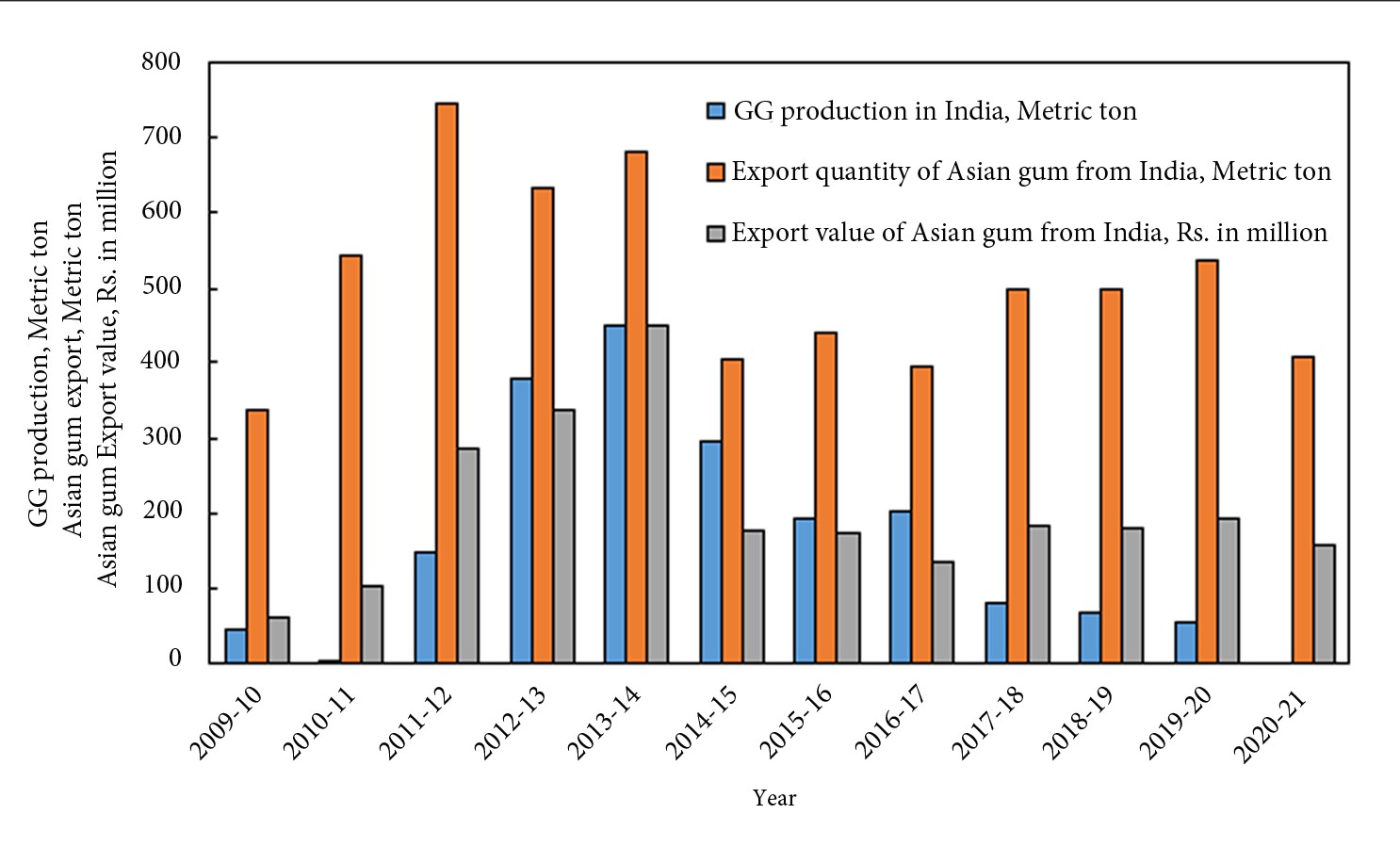

The GG production and export data for Asian gums, including GG in India, is presented in Fig. 6. The production of GG increased from 43.3 metric tons in 2009-10 to 448.41 metric tons in 2013-14 and later started declining; and in 2019-20, it was only 54.0 metric tons (Yogi, Kumar & Sharma, 2021a). The reason for decline in the production may be attributed to the ban on gum tapping by different state forest departments to restrict excessive exploitation of trees. Further, the complete data related to production is not available as natural gum sector is not well organized and most of the gum production as well as consumption activities remain unrecorded. Though data on the export of GG from India could not be found, the data on the export of Asian gum, including GG and Acacia nilotica gum, were obtained from the Directorate General of Commercial Intelligence and Statistics (DGCIS), Kolkata, India (Fig. 6).

On average, during 2009-10 to 2020-21, India exported 510.45 metric tons of Asian gum (Yogi, Kumar & Sharma, 2021b) to different countries of the world (Fig. 7). India is also an importer of Asian gum, mainly imported from Indonesia and Singapore.

GG production and export data for countries like Pakistan, Nepal, Sri Lanka, Myanmar, and Bhutan could not be found during the literature review. However, the literature review revealed that in these countries, there are A. latifolia trees, which indicates that either A. latifolia trees have not been tapped for gum production, or production data has not been compiled and reported. Thus there appears to be scope for educating the farmers/forest dwellers about the scientific method of gum tapping from A. latifolia for their livelihood support and additional income. This will also enable an increased supply of necessary natural gum for application in different areas. The respective Government departments in these countries have scope to compile the GG production and export data, so that same are available for importing countries to meet their demand in different application. Further, it will also enable farmer/forest dwellers to get remunerative prices for their produce.

Figure 6. Production of GG in India and export of Asian gum (including GG) from India during 2009-10 to 2020-21.

Figure 7. GG producing, exporting and importing countries (Note: Created based on the data from DGCIS, Kolkata, India. (Yogi, Kumar & Sharma, 2021b)).

Conclusion

This review covers recent research carried out on production, processing, and marketing of Gum Ghatti (GG). It is a natural exudate gum, and its source is renewable. It possesses distinct properties falling between gum karaya and gum arabic. Further, processing, handling, and storage of GG is easy. In this review, a decreasing trend in GG production in India, a leading producer country, was observed, which is a matter of concern. GG is a unique product of several South Asian countries and has the potential to earn foreign exchange, encourage sustainable forestry, and restrict climate change. Due to its distinct property, safety record, and natural origin, GG finds applications in food, medicine, and industries. GG possesses enormous potential for sustainable development in South Asian countries. There is scope to develop methods for increasing GG production and bringing more area under A. latifolia plantation. This tree is found in dry deciduous forests. There is enormous scope for its expansion, as it helps in afforestation and atmospheric carbon dioxide fixation. To meet the future demands of GG, it is required to take up further research on the genetics, physiology, and breeding of this crucial tree. All over the world people have observed the importance of using natural products, and it is expected that the use of natural products like GG will increase in future, paving the way for flourishing this sector in time to come.

Acknowledgement

The authors acknowledge the financial support for the research project under the Indian Council of Agricultural Research (ICAR) - All India Network Project (AINP) on Harvesting, Processing, and Value Addition of Natural Resins and Gums.